Product Parameters Table

|

Category |

Details |

|

Brand |

Vogele |

|

Type |

Paver |

|

Year |

- |

|

Maximum Paving Width |

10m |

|

Emission Standard |

China Stage III |

|

Engine |

Cummins QSB6.7-C215 6-cylinder diesel engine |

|

Model |

Super 1880-3L |

|

Dimensions (L×W×H) |

7.06×6.96×6.86m |

|

Weight |

20960 kg |

|

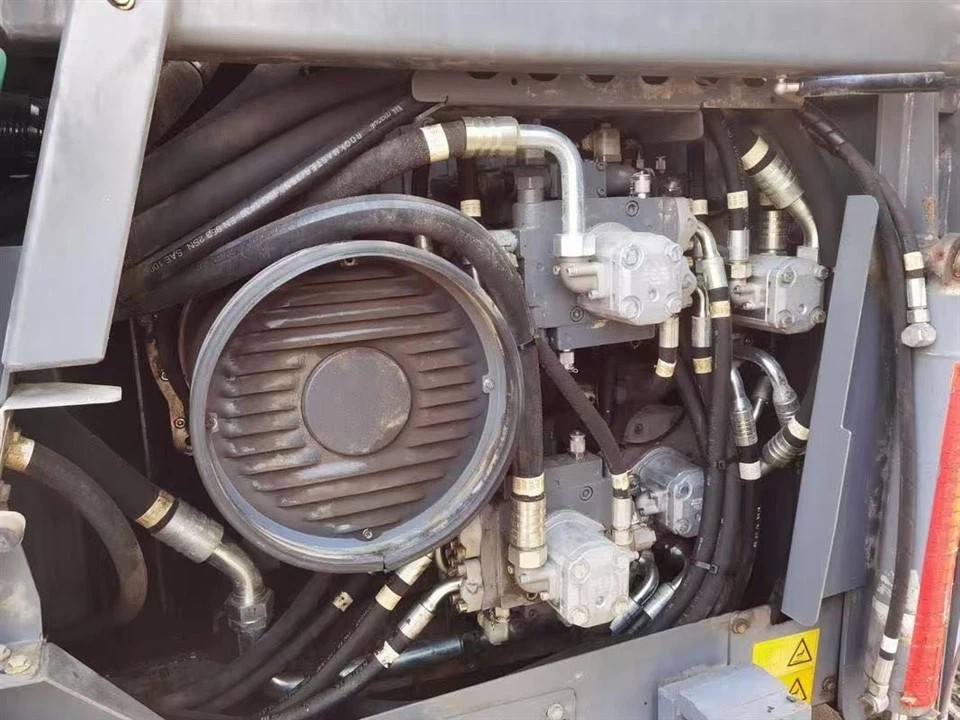

Travel System |

Rubber crawler, independent hydraulic drive; maximum paving speed 24m/min |

Product Introduction

As Vogele's classic medium-sized crawler paver, the 1880-3 is designed for high-grade asphalt paving, suitable for construction scenarios such as expressways and municipal roads. It combines high efficiency with energy-saving advantages. This used equipment has undergone professional inspection and maintenance, with intact core components, offering outstanding cost-effectiveness.

As a universal crawler paver in Vogele's "-3" series, it is designed for high-grade pavement construction. It can be equipped with AB 600 hydraulic telescopic screed or SB 300 mechanical extension screed, suitable for both asphalt and base course paving. Equipped with the ErgoPlus 3 control system and Niveltronic Plus automatic leveling system, it adapts to various scenarios such as expressways and municipal roads.

Configuration Details

15t Large-Capacity HopperAdopting a streamlined arc structure design, paired with a swing-type push roller device, it can buffer the impact of material trucks during unloading to avoid asphalt segregation. The 15t rated capacity can match a paving capacity of 1000t/h, reducing the frequency of material trucks' round-trip unloading, which is especially suitable for long-distance continuous construction. The inner wall of the hopper is treated with an anti-adhesive coating for easy cleaning.

ErgoPlus3 Control SystemAs the standard human-machine interaction system for Vogele's high-end series, it features a modular layout design: the main operation panel integrates knobs for adjusting core parameters such as paving speed and thickness, and is equipped with a high-definition LCD screen to display equipment status in real time. It supports multi-mode switching and can store 3 common construction parameter schemes, which can be retrieved with one click when changing working conditions. The control handle adopts an ergonomic design to reduce fatigue during long-term operation, making it user-friendly for novice operators.

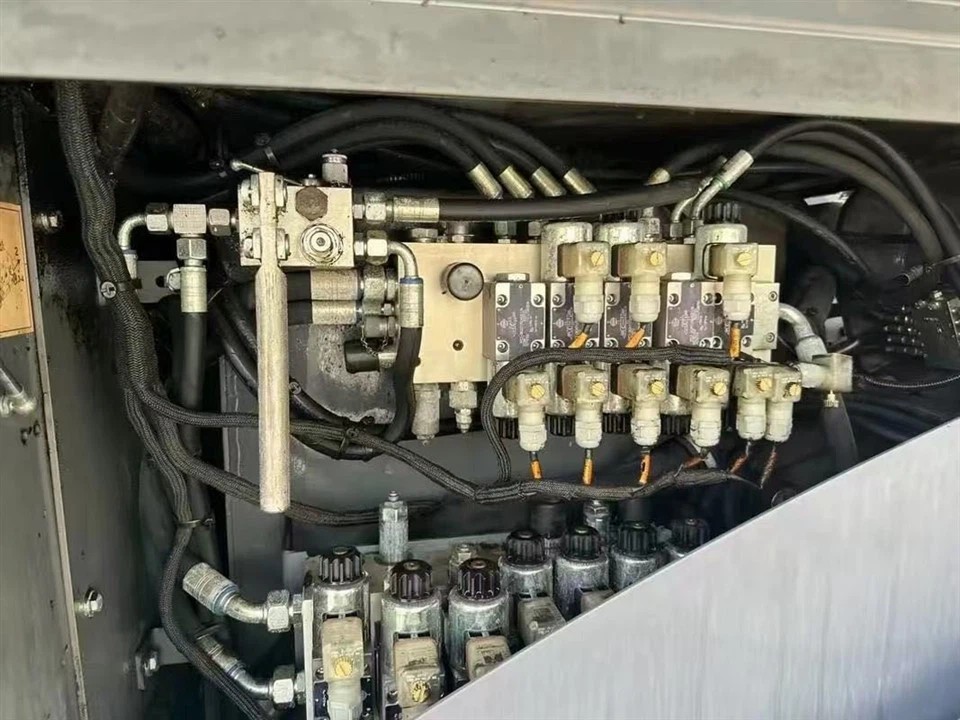

Niveltronic Plus Automatic Slope Control SystemThe core function is to receive road surface elevation signals through sensors, convert them into driving commands via the side control box, and control the hydraulic cylinders of the traction arm to adjust the screed's posture, thus compensating for flatness deviations caused by subgrade fluctuations. The system accuracy can reach ±0.5mm/m, and it supports linkage with 3D measurement equipment, meeting high-precision paving requirements such as those for expressways.

AB 600 Hydraulic Telescopic ScreedAdopting a single-sleeve telescopic system, the stepless width adjustment range is 3m-6m; with mechanical extension blocks added, the maximum width can reach 9.5m, meeting the needs of different road widths. It has built-in multiple sets of electric heating tubes, which heat up quickly and evenly to avoid local condensation of asphalt. The bottom of the screed is made of wear-resistant alloy material.